Orbica is a New Zealand-based company active in geospatial artificial intelligence (GeoAI), a field that combines geospatial technology with AI that optimizes traditional methods for object classification. Orbica’s solutions use supervised machine learning techniques enable object classification in geospatial imagery.

Automating construction site inspection and progress reporting

Last year, the company participated in a contest organized by a group of German corporations under the name BeyondConventions. During a two-day event, Orbica pitched a solution for a digital challenge created by thyssenkrupp, a large diversified industrial group that is active in 79 countries. thyssenkrupp was looking for a solution to automate reporting of build progress at large construction sites using emerging technologies to save on time on resources. Orbica won with a pitch for using AI algorithms traditionally designed for 2D imagery in a 3D context.

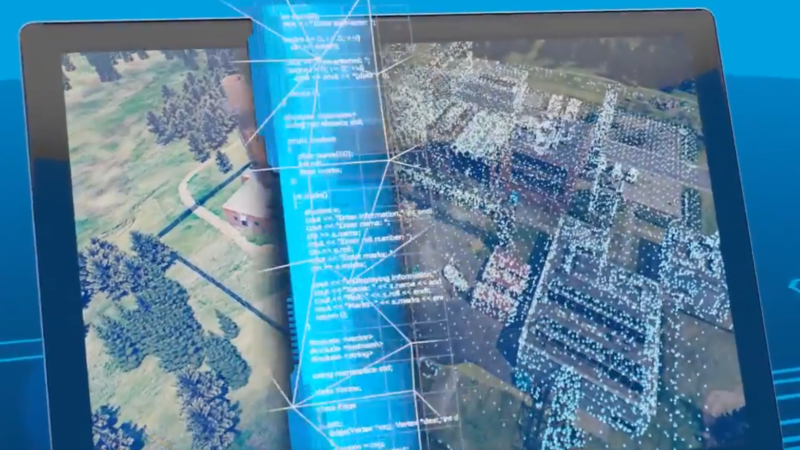

thyssenkrupp construction site

The company’s automated solution uses standard commercial drones and sensors and photogrammetry tools for generating 3D point clouds, instead of expensive drone-based lidar. After a drone flies a determined flight path, the imagery is uploaded and processed into a 3D point cloud of the construction site.

Next, Orbica’s AI engine uses algorithms trained by supervised machine learning to perform feature detection on the 3D data to classify basic materials to each point. The solution then uses GIS to compare these derived points with the 3D BIM of the site in order to determine how much progress was made. Finally, that progress information is used to generate a status report for the client, including a visualization and overview detailing the percentage of the total volume of the buildings outsides that have been completed.

Orbica data scientist Sagar Soni

Better site awareness

The solution makes it possible to check progress more often than would be possible through physical monitoring. It is now theoretically possible to realize weekly, or even daily, reporting instead of monthly.

More importantly, automated reporting has a higher accuracy and consistency than physical inspections allow for. “More frequent progress reports allow for more reliable checks of contractors and their status over time,” says Orbica’s European Director Peter Rose. “This information can be used for billing purposes, reduce timeline from staff and result in faster recognition of any possible issues onsite. The solution is also quite scalable, so once it’s been implemented, it can be produced for the cost of the drone and processing power. Finally, the high-resolution 3D point cloud can help improve internal and external communication.”

For more information, see Orbica’s site here.