Clymer Farner Barley (CFB) is a survey and civil engineering firm based in Central Florida. The company handles a wide variety of projects mostly around land development route surveying and construction staking. The surveying division at CFB was established in 2022 and now integrates both UAV lidar and static scanning in their workflows. The company plans to venture into mobile LiDAR in the near future.

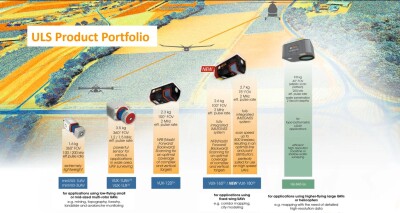

For a UAV lidar scanning project in North Marion Country (Florida), the company deployed the Riegl VUX 12023 airborne laser scanner, mounted on a Harris H6 Hybrid UAV. The data collected from this project will be utilized for environmental resource permitting through the Florida Department of Environmental Protection.

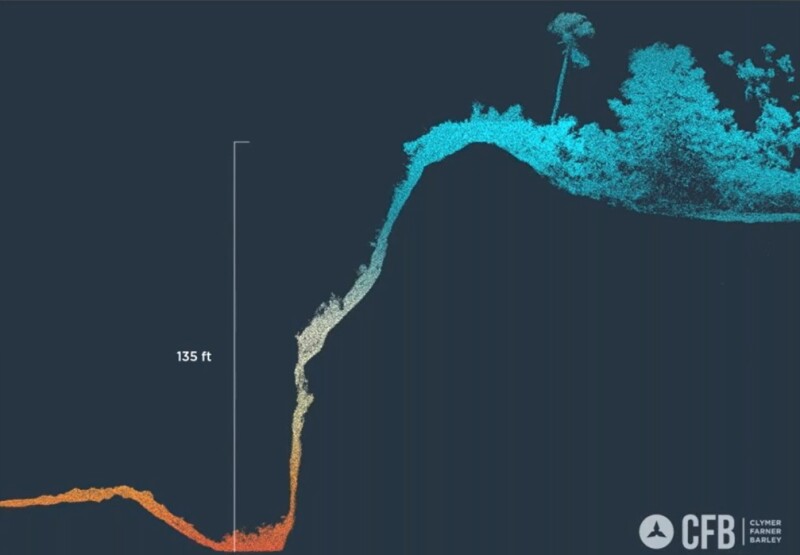

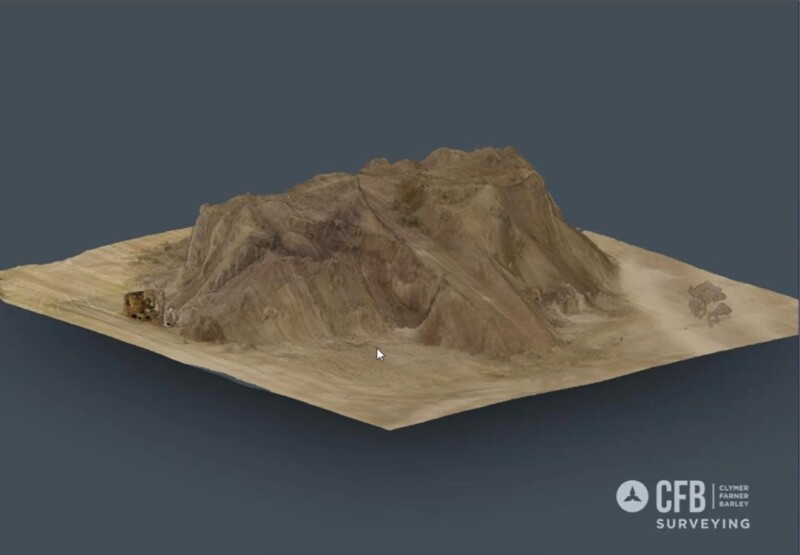

The project area contained a lime rock mine that is made up of five pits including three active mines. There was a wide variety of environments on this property, including significant elevation changes, with some of the walls of the mine being over 100 feet tall. The area also contains very dense vegetation, wetlands, roads, and more.

Excessive capture settings

The VUX 12023 utilized three separate lasers for data collection as well as very high capture rates up to 32 targets per pulse. For this project, CFB went excessive with its scanner capture settings: a pulse repetition rate of 2.4 megahertz was used, a line speed of 400 scan lines per second, at a flight speed of 13 miles an hour and a scan overlap of 50%, resulting in a ton of data to work with.

The settings used resulted in a point density of about 2,200 points per square meter. With these settings being intentionally excessive, the objective was to explore the capabilities of such high resolution in the project type, as well as to use the results for marketing purposes. As to be expected, the raw data turned out to be pretty substantial: prior to processing, the data volume was over 600 gigabytes.

Combing UAV lidar and conventional field crew work

The company’s geospatial team collaborated with multiple field crews whose primary task was to locate most of the improvements using the same control as the aerial targets to keep everything unified. Given the 100+ foot elevation drops, intense heavy equipment traffic within the active mines, and the extensive area to be recorded, the company opted for a combination of UAV lidar and conventional field crew efforts. This approach proved optimal for efficiency, cost effectiveness and safety. The integration of the conventional field data with lidar data proved to work out very well.

Data extraction process

For data extraction, the company experimented with various methods to achieve the best results while maintaining manageable file sizes. Ultimately, a variable grid size approach was adopted for the ground shots ranging from three feet in areas with significant elevation changes to 50 feet in more leveled regions. Despite this, it was necessary to divide the surface into multiple files, and reference of those into an overall surface to produce a usable product for the engineers. Working in a single drawing was inconvenient as it was too dense. The high data density made the scan data look like a 3D model.

Utilizing the VUX 12023, the scanner has consistently delivered exceptional performance, resulting in highly accurate data whatever point density suits the job. The ability to tailor the scanner to fit the various job types is essential to CFB’s workflow.

Resource: Digging Deeper: How RIEGL & Clymer Farner Barley are using the VUX-120-23 for Mining