Dimensional control has been with us since the Egyptians built the pyramids. Some work processes for dimensional control in the construction industry are as old as the sand under the pyramids. Poor dimensional control is a schedule thief and a budget buster. Is there any relief in sight?

Project responsibility for dimensional control is a hot potato. Project reality is that engineering CAD models are rarely perfect, fabricated components aren’t always made to spec, and in the field, what gets constructed doesn’t correspond to what was designed. The challenge of course is to manage the variances and changes safely within the

schedule, budget and performance requirements.

How can tight dimensional control help?

How can tight dimensional control help? The key is cost-effective, real-time updates to dimensional databases that can be checked against the design model. Consider the following scenario. A piece of equipment, a reactor vessel, say, is hoisted onto its foundation and sited. With today’s systems, millimeter location can be achieved in many instances. The next question is: Will the pipe spools fit? Do the flanges line up? Do the cable trays need to be modified? This can be sorted out on the jobsite – it often is – but creative construction and field fabrication is expensive. As Mark Klusza, president of BitWyse , puts it, “The 3D model may be perfect, but you can’t build perfect.”

A new way is to survey the precise location of all tie-ins with millimeter or sub-millimeter accuracy following installation, similarly survey the spools and vendor packages before they leave the fabrication yard, compare both data sets with the design model, and check for alignment and fit. If the spools aren’t the correct length, if the elbows are not at the correct angle, if the flanges don’t line up, then fix the problem before the spools leave the fabrication yard. The Mechanical Contractors Association publishes manuals that compare the time it takes to

perform shop welds with the time it takes to perform field welds.

Again, the key is cost-effective, real-time updates to dimensional databases that can be checked against the design model. The technology to capture field dimensions is getting both more accurate and faster. Here’s where rapid survey acquisition with total stations, laser scanners, GPS/RTK systems with small crews comes to the fore. Nothing new, you say? Look again – technologies to quickly compare field-captured and fabrication-yard-captured dimensions with the design model, and visualize and report variances, are just around the corner.

Business impact

The business impact of this will be most pronounced in business models that find profit in construction growth and engineering changes. Owners with significantly diminished appetites for construction growth will insist their contractors streamline dimensional control procedures

with faster, higher-quality job site surveys and management of differences between the as-designed and the as-constructed. Construction site survey to fabrication tolerances certainly doesn’t make economic sense in every instance, but there are many cases where it does. Hot work in offshore construction and time-sensitive turnaround work in refineries come near the top of the list. The issue goes beyond efficient construction – dimensional control can pay dividends by reducing maintenance on rotating equipment by reducing residual stress from poorly aligned piping and supports.

Keith Medley, general manager of HICAD America , observes, “With oil at its current price, getting into production is a high value. Reduced turnaround duration, reduced fabrication times, and reduced maintenance in the future provide robust front-end cost justification for good dimensional control programs.”

What is dimensional control?

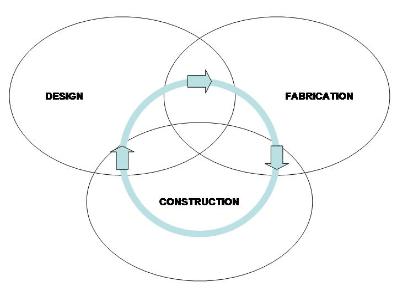

Dimensional control is a risk management process which, in its simplest form, is the collection of accurate 3-dimensional data sets in order to allow a comparison of the “as-built” or

“construction-in-progress” model with the theoretical model.

In the case of new construction, dimensional control begins with design where dimensions and fabrication tolerances are specified. The goal is design integrity assurance driven by the requirement for the as-built model to demonstrate deviations from the theoretical model which will not significantly affect designed load paths.

In the case of revamp work, dimensional control usually begins with a survey, laser scan or other data collection method of the existing conditions which determines the boundary conditions and tolerances for subsequent design.

The next phases of dimensional control are fabrication followed by construction. Dimensional control of fabrication involves a survey or measurement of the manufactured component to determine if it meets the required design specification, i.e., nominal dimensions within

specified tolerances. The construction phase of dimensional control is onsite measurement to assist in properly locating, leveling and aligning foundations (including bolt patterns), equipment, components and piping. The process also addresses constructability and sequencing including issues such as lift plans for heavy equipment, access and modular construction issues.

Dimensional control procedures include the specification of measurement tools, calibration requirements and procedures necessary to achieve the required results. For example, a typical

dimensional control process might specify the use of a well defined field procedure, and may also designate accuracy requirements of a total station to locate and capture the orientation and bolt rotation for flanges.

Origins of dimensional control

Some industry experts trace the origins of modern dimensional control to the tragic Piper Alpha explosion on July 6, 1988 in which 167 people died. After that accident the oil and gas industry looked for new ways to reduce the requirement for field work under hot conditions. Dimensional control was seen as a way to reduce the requirements for hazardous field operations such as cutting and welding of pipe spools. Cost is certainly a driver as well as safety. When getting to a production facility is a 2-hour helicopter trip or 12-hour boat ride, there is no small economic incentive to ensure that components fabricated onshore will fit when they show up on the jobsite. Much of the world’s expertise in dimensional control and management systems comes from the North Sea region. HICAD, headquartered in Dingwall, Scotland, has established offices in Houston.