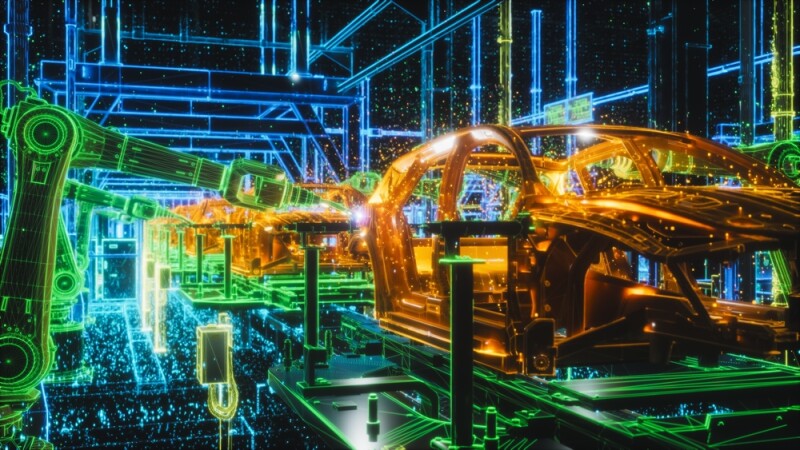

Boston, Massachusetts | April 10, 2025 - Today, the Digital Twin Consortium® (DTC) announced NTT Data’s Technology Showcase titled Digital Twin-Enabled Microfactory for Smart Manufacturing. The showcase demonstrates the capabilities and benefits of composable digital twins in asset-intensive industries, including manufacturing, mining, oil and gas, and utilities. It also demonstrates how digital twins can improve operational efficiency, predictive maintenance, and automation in production lines.

“NTT Data’s digital microfactory is a global innovation initiative aimed at developing long-term technology strategies, enhancing R&D efforts, and fostering collaboration within an

innovation ecosystem,” said Dan Isaacs, GM & CTO of the DTC. “The composable architecture of the Digital Twin-Enabled Microfactory for Smart Manufacturing allows adaptation to different industrial use cases based on DTC’s Capabilities Periodic Table (CPT).”

“Through this technology showcase, NTT Data aims to bring our manufacturing knowledge into a portable, modular, and comprehensive asset that will allow us to provide and test applicable technologies from the perspective of digital twins,” said Carlos Toro, Ph.D , Head of Data & Analytics, NTT Data (Chile). “The technology showcase can be used to train operators, test the newest technologies, and share outcomes with the digital twins community. Also, the use of AI including Generative AI and Agentic approaches will be shown, for example in the enhancement of repeatability in the SCARA manipulator present in the microfactory. The initial idea of this testbed was developed in Chile and it has been replicated in other NTT Offices around the world thanks to the coordination of the Global NTT Data Innovation Center.”

The Digital Twin-Enabled Microfactory for Smart Manufacturing integrates IoT sensors, PLCs, and an IoT gateway to enable real-time data streaming and edge computing. It utilizes composable architecture, AI-driven insights, and 3D visualization to optimize production processes, detect anomalies, and support predictive maintenance.

As a synchronized virtual replica of the microfactory, a digital twin enables real-time monitoring, process optimization, predictive analytics, and remote operational control. Its edge-to-cloud capability ensures scalability and efficiency across various industrial environments. Real-time monitoring and anomaly detection reduce downtime and improve productivity for enhanced operational efficiency.

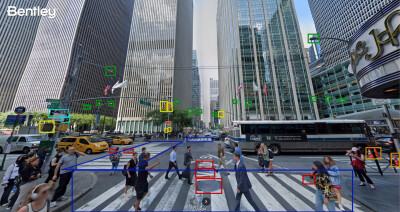

AI and ML algorithms help preemptively identify faults, ensuring proactive intervention for predictive maintenance. The tech showcase uses environmental telemetry dashboards, real-time dashboards, and 3D immersive experiences for remote monitoring at the edge. It Integrates computer vision models to identify misalignments and generate real-time alerts for fault detection in a production line for edge-to-edge migration. It uses a hub-and-spoke architecture to optimize communication, security, and data transmission for XMPro integration.

View the Digital Twin-Enabled Microfactory for Smart Manufacturing on the DTC website. Become a DTC member and join the global leaders in driving digital twin evolution and enabling technology.

Digital Twin Consortium

Digital Twin Consortium® (DTC) is Accelerating Digital Twin Innovation™. DTC executes the promise of digital twins and associated technologies by working closely with our members to accelerate the market. We foster development, raise awareness through impactful work products, and drive increased digital twin adoption across industries. DTC is a program of Object Management Group®. For more information, visit https://www.digitaltwinconsortium.org.

Source: Press Release