One of the fastest growing technologies across all industries right now is digital twin technologies, which Fortune Business Insights indicates is poised to grow to an estimated $94.49 billion by 2029, compared to $6.75 billion in 2012, a compound annual growth rate (CAGR) of 40.6 percent. Much of this growth is likely due to the technology’s place in developing the metaverse, but even now there are a plethora of value-adds that can benefit businesses, such as saving costs during construction and throughout the life of a building with early detection of possible maintenance issues.

Those certainly are not the only use cases for digital twins, though, as the real-time sensors that differentiate these from BIM models can provide a lot of other useful information. One such example of this is with Digital Energy’s recently-released ODIN Safety tool, a health, safety, and environment (HSE) application.

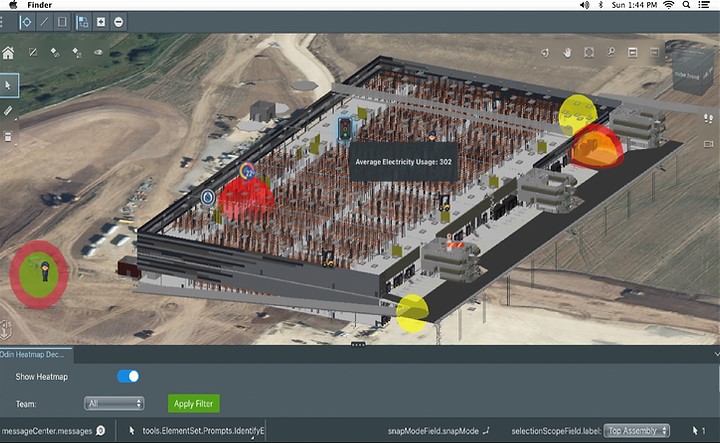

ODIN is an application from Digital Energy, and powered by the Bentley Systems iTwin platform, which combines digital twin data with artificial intelligence (AI) to help predict and avoid potential industrial accidents in enterprise environments. After creating an accurate digital twin with reality capture scanning, users can manage up-to-date virtual representations of physical assets within their facility with the ability to integrate data from a variety of different sources and formats. That data can then be fed into ODIN’s AI systems, which use the information to predict potential hazards and accidents on a job site. Safety for workers always has to be the top priority for any manager in a facility, and having this kind of predictive information available can prove to be an invaluable resource to that end.

ODIN’s platform, which can be utilized on a variety of different devices, also allows for easy collaboration and usage across different stakeholders. This is itself also adds another layer to making the workplace a safer environment, as shift changes can now happen more smoothly with the next team being able to start their shift with all of the pertinent information at their fingertips. In addition, shift leaders have immediate access to the information processed through ODIN’s AI systems, allowing them to have readily available any potential incident or accident site in the facility from the get-go.

Digital Energy, headquartered in Dubai, UAE, with another office in Dublin, Ireland, was founded in 2016 and was, in their words, “a response to the need to reduce industrial inefficiencies.” The company uses AI to help optimize environmental good practices with economic benefits. They work with a number of different industries, including energy, utilities, logistics, and construction, all of which of course fall under the AEC umbrella which McKinsey called out for a lack of efficiency on projects back in 2016. Since that report was released, companies from all over have been seeking out these kinds of applications that can be used to streamline their production while also making the workplace a safer place for their employees.

The AI is a big part of this ODIN Safety feature to be sure, but of course that is enhanced by the data which comes in via the digital twin platform. Like many other new digital twin platforms on the market, including SmartViz and plenty of others, ODIN has partnered with Bentley Systems and is utilizing their iTwin platform. The iTwin platform serves as a building block for many new digital twin solutions, providing the foundation on which the tool is built. Taking care of some of the logistical challenges of developing a digital twin solution, such as back-end security, infrastructure, and data integration needs, Bentley allows companies to focus on the application itself to provide the use cases its customers are seeking. That, in turn, lowers the amount of overhead needed for things like building and maintaining the IT infrastructure.

As the digital twin market continues to rapidly expand, we are sure to see more and more use cases being developed, with ODIN’s Safety and its combination of AI and digital twin for HSE needs representing just one of the latest. As Sheena Gaynes, Director of Buisness Development of the iTwins platform at Bentley Systems said in the announcement of the partnership, “The ODIN Safety application is a great example of how digital twin technology can help industrials to harness the power of AI to optimize operations and increase workforce safety.”