Contributed by Advanced Navigation

Key Points

● The Spatial FOG Dual inertial navigation system provided a 10 to 15x improvement over MEMS based heading during dead-reckoning.

● A challenging set of requirements led to Ultrabeam developing a unique autonomous and amphibious survey vehicle that required a carefully selected and integrated sensor suite.

● The compact size and low weight of the Spatial FOG Dual lends itself to being transplanted into other survey vehicles, including aerial types.

● Success of the project led to Ultrabeam being able to offer their clients above and below water 3D digital twins, including water current and velocity data and substrate measurements, in a single pass.

Ultrabeam Hydrographic (UK)

Ultrabeam Hydrographic was established in early 2018 by Gabriel Walton and Andy McLeay, who between them share over 45 years of experience in the coastal and offshore survey industry. The company was formed to deliver high-quality hydrographic and geophysical survey services to a wide range of clients, from ports and harbours, utilities, offshore renewable energy, oil & gas and public sector marine industries. Accurate hydrographic surveys are vital for the maintenance of marine assets such as bridges, docks & harbours, offshore installations and oil and gas platforms. From day one, the company has focused on a specific and revolutionary method of conducting these surveys using unmanned survey vessels (USV) that Ultrabeam has designed and built itself. Using USVs to perform this type of specialist survey and inspection is much more efficient than traditional methods and is also safer, particularly in hazardous conditions. Ultrabeam has combined this innovative acquisition approach with cutting edge data processing and visualisation platform to provide deliverables which outperform anything currently available within the marine industry.

The challenge: Building a hydrographic survey-anywhere vehicle to assist defence forces in safely crossing wet gaps

Defence departments are always looking to seek advantages in improving the safety of armed forces personnel and equipment in regions experiencing conflict. To this end, in 2020 the UK Defence Science and Technology Laboratory (Dstl) launched its “Map the Gap'' competition, inviting engineering firms to design and build a vehicle capable of quickly, reliably and safely surveying “wet gaps” (rivers, streams, canals and waterways) without putting reconnaissance engineers and other personnel, such as divers, at risk. The survey data can then be viewed and the best and safest points for crossing of troops and equipment can be determined. This is a critical consideration for armed forces as crossing wet gaps, which is a notoriously slow exercise that typically places personnel and equipment waiting to cross vulnerable to attack.

Some of the parameters around the challenge include taking measurements and gathering data for water depth and flow rate, crossing length, river-bed topography, river bank height and shape profiling and how much load the ground is capable of handling. The vehicles also had to be either remotely operated or autonomous, with emphasis on developing autonomous systems as widely as possible, and had to deliver the collected data in a way that could be easily interpreted for quick decision making. Apart from the practical aspects that the robot had to attain, innovation of the vehicle design was assessed, as was the ease of repurposing the sensors to other vehicles of opportunity. Cost of the solution was also capped.

Ultrabeam has many years of experience in the hydrographic survey industry and has a long history of building bespoke vehicles (sea, land and air) for specific data collection purposes and outcomes, which put them in a highly competitive position.

1. The first phase of Map the Gap required competitors to demonstrate a robotic vehicle that could satisfy the desired capabilities from which, after trials, the best candidates would be selected for phase two.

2. The second phase required a clear plan to a technology readiness level and how the vehicle could be developed for in-service use. Additional field trials in an appropriate environment that included the vehicle entering and exiting the crossing site also had to be met.

The challenge is multi-faceted and requires multiple sensor technologies for simultaneous above and below water 3D surveys.

● For above water, dual LiDAR sensors produce high resolution point clouds of the surrounding environment.

● For below water mapping, current and water flow measurement and substrate density testing, the sensor suite comprises a multibeam sonar, ADCP/DVL (acoustic Doppler current profiler/Doppler velocity log), and cone penetrometer. As a payload, the sensor package was unlikely to be suited to a UAV (uncrewed aerial vehicle) and an USV (uncrewed surface vessel) would require being deployed and retrieved at the water’s edge, exposing personnel to danger, so an amphibious design was chosen.

Ultrabeam wanted the sensor package to be vehicle agnostic, so it could be swapped to other vehicles as required and basically integrated as many of the sensors as they could into a single housing. They went on to select a proprietary robotic chassis that could handle the payload and suitably traverse difficult terrain such as mud and sand, float and be suitably modified for purpose. The team used an 8-wheeled chassis in phase one (project Argonaut) that shrunk notably to a more easily deployed 4-wheeled vehicle for phase two (project Axolotl).

The solution: FOG technology improves Axolotl dead-reckoning performance

Selecting sensors and data acquisition equipment that is fit for high-resolution hydrographic survey is something that Ultrabeam are very good at. The utopia of specification sheets, however, can quickly crumble in the rigours of field work, so Ultrabeam makes sure to thoroughly test each sensor package against its listed specifications before incorporating it into a design.

With the Axolotl, there is a lot of data being generated from the various sensors, all of which must be accurately geo-referenced for location and heading. Being a defence based application, operation without reliance on GNSS is required, so dead-reckoning of the navigation system and maintaining accurate heading is of critical importance. For this reason and for overall high performance, Advanced Navigation Spatial FOG Dual was selected. In comparison with a MEMS based heading solution that Ultrabeam had available, the MEMS device could maintain suitably accurate dead-reckoned heading for up to approximately 60 seconds, whereas tests with the Spatial FOG Dual increased dead-reckoned heading performance to almost 15 minutes.

“The MEMS can hold onto heading for maybe 30 seconds to a minute, accurately. But after that, it's not reliable. We have used the Spatial FOG Dual in certain circumstances where we went 10 to 15 minutes without GNSS. I do believe it will go on for longer.” states Gabriel Walton, Technical Director, Ultrabeam.

The optical gyroscope technology of the Spatial FOG Dual has no moving parts and this makes it less susceptible to shock and vibration induced errors. The Axolotl is a very short wheelbase vehicle and this creates a tendency for it to change direction and orientation very quickly on rough terrain, which can be difficult for some systems to accurately resolve. Similarly, when the bow and stern sections of the Axolotl are extended into watercraft mode and it is in water, the robot is still prone to arbitrary movement and drift due to water current, surge and heave, and where heading and direction of actual movement is not congruent. These are factors that can make dead-reckoning for small watercraft extremely difficult.

Form factor and ease of integration are important considerations for a robotic vehicle like the Axolotl. The philosophy of the Ultrabeam team is to repurpose equipment when convenient and satisfactory. That is, moving their inertial labs and survey sensors between vehicles as fit for purpose at the time. In this case, the compact size and relatively low weight of the Spatial FOG Dual immediately lends it to applications outside of Map the Gap. The Ultrabeam team had a software driver written to allow them to plug the Advanced Navigation system into their survey management and mission control software for not only survey purposes but also to provide motion data into the robot AI for autonomous mission control and object detection and avoidance.

The result: A preferred solution for a complex and challenging autonomous surveying project

The results of the Map the Gap phase two robot assessment and field trials led to Axolotl being recognised for its capability in accomplishing the required survey and measurement tasks, design innovation, and implementation. Mechanics aside, the sophisticated sensor suite integration and heavy use of AI logic and reasoning systems for autonomous mission control and decision making, and navigation are testament to a cutting edge design approach and leveraging the latest sensor and computing technologies.

“We pitch ourselves on being the best in very difficult environments and it's not just about data collections. There's so much in it. We are always looking for the best navigation solutions to help us create better vehicles.” says Walton.

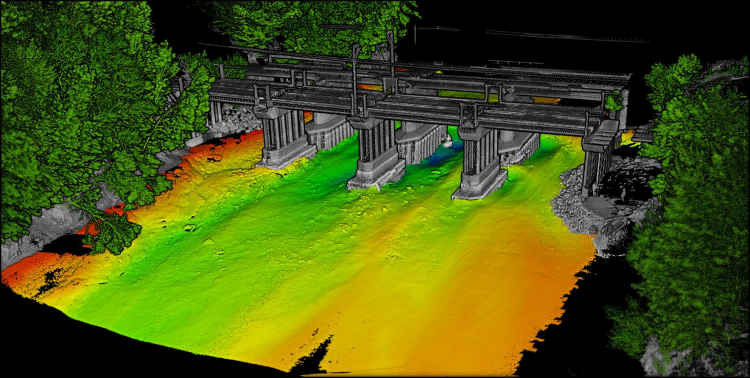

Since Map the Gap, Ultrabeam have deployed the Axolotl on commercial waterway survey missions. For example, surveying bridge sites, including the underside of the bridge, pylons and footings and also attaining a clear understanding of the river bed and prevailing water conditions around bridge footings and river banks. The fact that the Axolotl can do this (and more) in a single pass, from a single survey contractor, makes it not only highly efficient and a big money saver for clients but also from a data and measurement coherency perspective, where all data types are being acquired from the same position and point in time. The long duration dead-reckoning heading accuracy of the Spatial FOG Dual is essential to maintaining the course of the Axolotl during extended under bridge operations, where GNSS is typically unavailable or very poor.

In some commercial survey circumstances, the team will use a robotic laser total station located on the river bank to provide additional tracking of vehicle position during the mission. The total station fires out a laser that reflects off a prism mounted to the Axolotl to provide a very accurate secondary position, from a fixed point of reference. This additional position data is used during post-processing to further improve accuracy of the navigation data, particularly in conditions that are choppy or windy. Having a secondary data source helps further attenuate signal noise and extraneous movements that are not part of the actual navigation, but are still being sensed.

The Axolotl project has not only reaped dividends and accolades from its competing in Map the Gap but has strengthened Ultrabeam’s survey vehicle arsenal. Through selecting the right components for the task at hand with a vision of future possibilities and carefully integrating each sensor package into a sophisticated AI mission control system, Ultrabeam have created a unique, robust, uncrewed autonomous hydrographic survey vehicle that is capable of multiple surveys at once on land and in water.

The Product - Spatial FOG Dual

Spatial FOG Dual is an industry-proven GNSS/INS and AHRS. It combines high accuracy fibre optic gyroscopes, accelerometers, magnetometers, and a pressure sensor with a dual antenna RTK GNSS receiver. These are coupled in an AI-based fusion algorithm to deliver accurate and reliable navigation data. Spatial FOG Dual is compatible with our post-processing kinematic (PPK) software Kinematica.

Spatial FOG Dual is an industry-proven GNSS/INS and AHRS. It combines high accuracy fibre optic gyroscopes, accelerometers, magnetometers, and a pressure sensor with a dual antenna RTK GNSS receiver. These are coupled in an AI-based fusion algorithm to deliver accurate and reliable navigation data. Spatial FOG Dual is compatible with our post-processing kinematic (PPK) software Kinematica.