Sponsored by Mach9

Recent years have seen a steady growth of developments in the world of robotics and, more broadly, automation. Whether it be UAVs, autonomous vehicles on the roads, ground robots completing tasks on construction sites, or many other use cases, developments in the hardware and corresponding algorithms have brought the space forward in ways that echo science fiction. Although there’s no one central location where this innovation is taking place, Pittsburgh, home to Carnegie Mellon University, would be on the short list to take that title.

The Robotics Institute at Carnegie Mellon has helped produce some of the most groundbreaking advancements and innovative thinkers in the tech industry today, with Mach9 being part of this group. The company was founded by Alexander Baikovitz, Haowen Shi, Michael Mong, and Zachary Sussman, who met while at Carnegie Mellon, with the mission to “build the fastest tools to create maps,” according to Baikovitz. The company started building mobile mapping hardware systems. It’s that experience which ultimately led them to pivot towards software and developing their new Digital Surveyor product, which Baikovitz says is “creating a new space of automated geospatial production.”

Pivoting towards a new niche

Digital Surveyor, at its core, is a powerful yet easy to use product. Taking in lidar and imagery data, the software can turn unstructured 3D data and turn it into schematics, CAD, or GIS. Before getting into the nuts and bolts of the offering, though, it’s worth thinking about the philosophy of Digital Surveyor.

Mach9 started out in the hardware space, giving them a unique perspective about the needs of the mobile mapping industry. Baikovitz tells Geo Week News that they noticed the process of manual drafting had traditionally been a “really slow and inefficient process.” Working with clients, they had seen first-hand what customers were going through to turn lidar data and other imagery into the crucial deliverables they hand off to their clients, designers, asset managers, or whoever else needs this information.

Continuing, he said that while firms with decades of LiDAR experience have developed established production workflows, that wasn’t the case for everyone. “3D is the new big thing and is becoming more accessible and cost effective with the growing availability of UAVs and mobile mapping– a lot of existing solutions to make maps were slow, local applications, not necessarily the most accurate and efficient. What we wanted to build was a fast, high-performance, incredibly accurate, cloud-based application to accelerate how people create maps, to make maps 30 times faster than the previous industry standard. That’s what Digital Surveyor is all about.”

Baikovitz likes to say that Digital Surveyor is going to serve three key purposes. First is to improve access to geospatial content. Second, they want their customers to be able to deliver insights from these types of maps and models created by lidar and imagery data, such as finding key features and understanding complex datasets. And finally, Mach9 wants to ensure the product can be integrated with other established solutions, offerings from companies like Autodesk, Bentley, and Esri, among others.

Emphasizing Geospatial Production

Now, with the problem clearly identified, Mach9 set out to create the solution that could stay true to the three purposes noted above and enable geospatial production by firms of all experience and size. The result is a unique solution that Baikovitz says is “ among the first” software that is able to automatically extract 3D features from imagery and lidar data together, crucially being able to do this while remaining OEM-agnostic.

There’s no doubt the group’s experience in the world of robotics broadly, and more specifically their time working in hardware, helped here as well. Asked why he believes it took until now to create this kind of algorithm, Baikovitz said, “A lot of us came from autonomous driving, robotics-related industries where, effectively, these industries had fostered more of these learning-based techniques for understanding imagery and spatial data.” In other words, it was a perfect confluence of timing, given the rapid advancements of learning-based techniques, and their experience on both sides of the geospatial landscape.

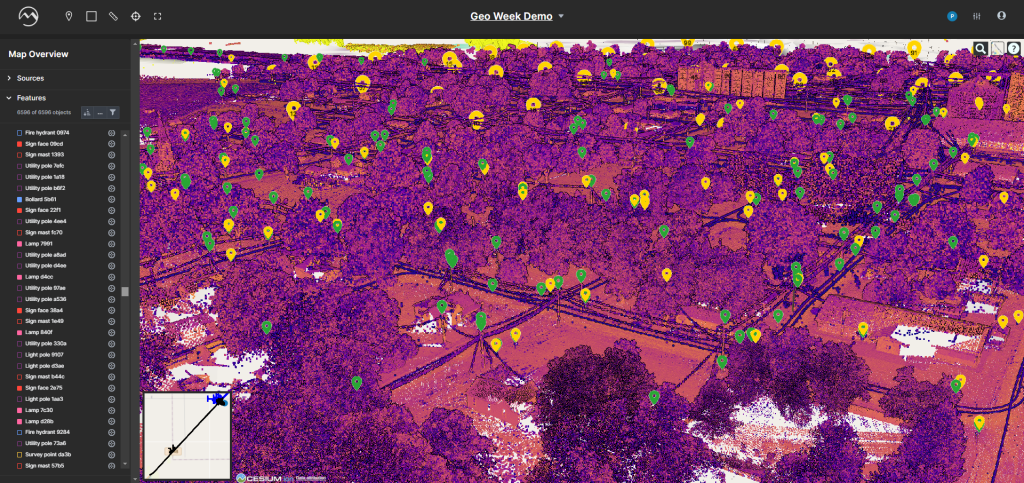

Functionally, Digital Surveyor carries out three primary objectives for dealing with lidar and/or imagery data. The first is organizing data. These datasets are massive and complex, making it difficult to simply organize it before even getting into the analysis piece. From there, the solution’s algorithms can automatically extract key features within the data that the end user needs to identify. Digital Surveyor includes a library of objects that can be identified, which continues to grow based on feedback and needs from users. Finally, quality assurance and quality control are front-of-mind, ensuring end users are getting their deliverables to the quality they need in order to complete their projects.

Digital Surveyor in Action

While Digital Surveyor is not yet available for wide release – that’s expected to come in Q2 of this year – Mach9 is working with partners that are currently using the product in the field to help refine it and ensure it’s ready to achieve all of its goals.

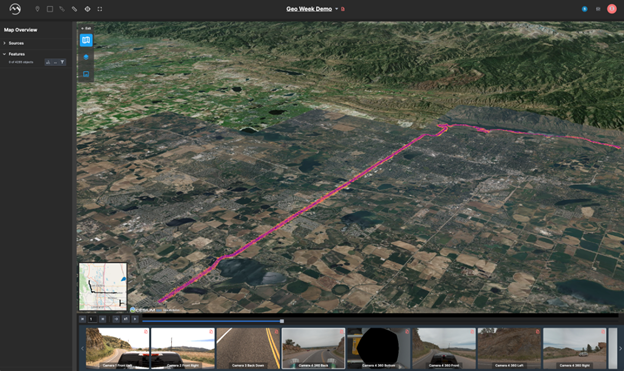

Aaron Chamberlin, a Senior Transportation Engineer with Caltrans, relayed to Geo Week News how his organization is using Digital Surveyor. Chamberlin told Geo Week News that Caltrans would be holding a pilot for Digital Surveyor which will encompass multiple projects and include about 100 miles of data collection. The projects will be varied in nature in order to “ensure the program works on the wide variety of terrain” present in California, with Digital Surveyor primarily being used to scale automated feature extraction.

Fibersmith Engineers is one such customer. Nick Pena, Vice President with the company, spoke with Geo Week News over email to discuss his experience using Digital Surveyor. Pena says that they’ve used the solution for multiple projects, all of which “support the design and construction of Fiber to the Home networks across the country.”

He continued, “We’re using Digital Surveyor to allow our field collectors to go faster and see more without having to decide what’s relevant. Our collectors are capable now of moving at the speed their vehicles will take them (not just their legs), producing a dataset that Digital Surveyor will work with. Digital Surveyor identifies the features we ask it to, without being constrained by what might be relevant to the current project. This allows our network designers to make sound decisions as though they were designing it from the field. If they wish to reevaluate a choice they made, they can virtually revisit the location in Digital Surveyor and look at it from a different angle.”

For his part, Pena ultimately identifies two problems being solved by Digital Surveyor. First, he says, it allows the team to “run faster on collection,” reducing costs while simultaneously extending their coverage area. Second, he says they’re no longer constrained by what field surveyors understood was relevant to the project at hand. “Digital Surveyor helps us perceive everything along the route.”

Learn more about Digital Surveyor, and check out our website below. To schedule time to meet the team and learn more about how Digital Surveyor can support your projects, please reach out directly to [email protected].

Learn more!