The TerrainMapper-2 is Leica Geosystems’ latest modular sensor offering. Here, Product Manager Ron Roth explains the concept behind the system, how users can upgrade from the new Leica TerrainMapper-2 to the new CityMapper-2 and how to do post-processing of large datasets.

Apart from integrating LiDAR and imaging for regional mapping projects, the new Leica TerrainMapper-2 offers a simple upgrade path to oblique imaging system. Leica Geosystems product manager Ron Roth explains the concept behind the new release and how it compares to the previous TerrainMapper release:

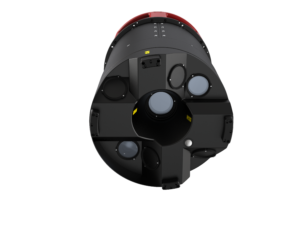

“The Leica TerrainMapper-2 concept is quite similar to the original TerrainMapper. However, based on the experience we gained with the previous system and the Leica CityMapper-2, we implement substantial performance improvements for the new sensor generation. The original TerrainMapper included a Hyperion2 LiDAR unit and a Leica RCD30 4-band imaging system. The new generation sensor features an upgraded Hyperion2+ LiDAR unit and the new Leica MFC150 imaging system, both of which contribute to significantly enhanced LiDAR and imagery data products.”

“The Leica TerrainMapper-2 concept is quite similar to the original TerrainMapper. However, based on the experience we gained with the previous system and the Leica CityMapper-2, we implement substantial performance improvements for the new sensor generation. The original TerrainMapper included a Hyperion2 LiDAR unit and a Leica RCD30 4-band imaging system. The new generation sensor features an upgraded Hyperion2+ LiDAR unit and the new Leica MFC150 imaging system, both of which contribute to significantly enhanced LiDAR and imagery data products.”

He adds that the general LiDAR system specifications, such as the pulse rate and the flying height, have not changed.

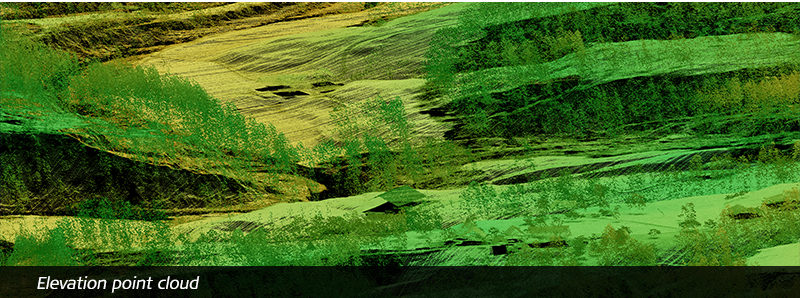

“However, with better close-range noise detection and suppression, the data quality has significantly improved. This increase in noise suppression performance allows us to use lower detection thresholds to get higher sensitivity, which in turn enables better foliage penetration, enhanced fine-feature detection and increased multi-return performance. Close range backscatter affects all gateless multi-pulse-in-air LiDAR systems, so this new technology is very important.”

Additional improvements

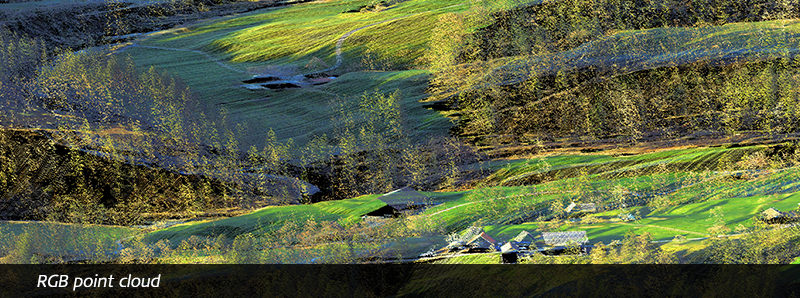

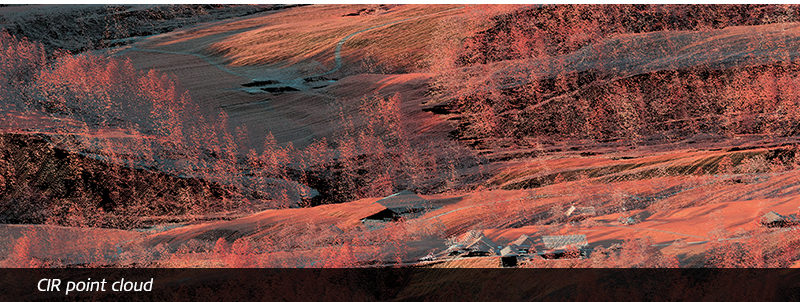

With the introduction of the new MFC150 camera heads (RGB, NIR) which were originally developed for the CityMapper-2, the imaging components have also significantly improved. The optical system provides outstanding image quality and is unique in its ability to use longer exposure times in low-light conditions without the resulting image motion blur. This is possible, thanks to Leica Geosystem’s unique mechanical forward-motion-compensation (FMC).

The system design has also been enhanced by integrating all system controls and data logging functions into the sensor pod, reducing external cabling and system weight. In addition, the backbone of the sensor has been further developed, leading to increased stability over the wide range of temperatures and vibrations seen during operation.

There have also been improvements in the Leica PAV100 stabilising platform which helps maintain an accurate vertical orientation and reduces effects from aircraft vibration, preserving the high resolution of the MFC150. All these changes increase the flexibility of the sensor and provide better performance over a wider variety of projects and applications, whether dictated by the required point clouds or image products.

Flying window

Allowing users to fly longer during each day, this sensor enables the capture of high-quality orthophotos during LiDAR flight missions with fewer impacts on flight schedules. Roth explains how long can you fly during a day with the system under different scenarios:

“The flying window depends on many variables such as season, latitude and weather conditions. With the new MFC150 optical system, we have captured very high-quality images with sun angles of 27 degrees, a much lower illumination than most data purchasers would expect. To put this into perspective, the mechanical FMC would allow us to fly in Denver, Lisbon or Beijing on December 21st (i.e., a 27-degree solar angle at noon) and still be able to get 2 cm GSD imagery at 180 knots using a 1/200 second exposure for high sensitivity. Without mechanical FMC, the same shutter speed would result in about 23 pixels of image blur. Going to a faster shutter speed (e.g., 1/2000 second) would result in under-illuminated and noisy data with 2.3 pixels of image blur. This is an example from a challenging, but not unrealistic scenario.”

How to upgrade from the TerrainMapper-2 to the Leica CityMapper-2

The system offers a seamless upgrade path to the Leica CityMapper-2, the market’s only oblique imaging and LiDAR hybrid sensor. asking what would be a logical scenario to upgrade from one to the other, Roth explains that the CityMapper-2 system is specifically designed for high-performance hybrid urban mapping applications:

“Hence customers would upgrade to this configuration if they had 3D city mapping projects lined up. The modularity of the TerrainMapper-2 and CityMapper-2 systems offer our customers great flexibility, a scalable investment and a simple upgrade path. Just like the TerrainMapper-2, the CityMapper-2 features the Hyperion2+ LiDAR unit, two nadir MFC150 camera heads (RGB, NIR), and in addition, four oblique MFC150 cameras for the creation of 3D products.”

This makes the sensor upgrade of the TerrainMapper-2 to a CityMapper-2 very straightforward, explains Roth: “Depending on the anticipated flying heights for urban mapping projects, the customers decide which CityMapper-2 configuration they want to upgrade to: CityMapper-2S or CityMapper-2H, respectively, about 1,500 m or 1,900 m AGL for a 5 cm GSD. This selection will determine the focal length for the new nadir and additional oblique lenses. We then ship the additional four oblique cameras, cover glasses, the new nadir RGB lens and the cables to the customer site. A Leica Geosystems customer support engineer will install the new camera modules on-site into the existing sensor pod and prepare the system for a calibration flight. The flight is used to establish the IMU/camera misalignment parameters for each camera head. The calibration flight data is processed, and a new calibration file is generated, after which the system is ready for operation.

Processing large data sets at the highest speeds

As part of the RealTerrain solution, the TerrainMapper-2 combines with the unified multi-sensor post-processing workflow, HxMap, to process even the largest data sets at the highest speeds. This is explained through a real-life example discussing the processing speeds, time savings and the benefits of edge computing for users of TerrainMapper-2:

“Naturally, processing speeds will vary depending on the IT configuration used and the products that are generated. If run on a single processor, which of course we would not recommend for any modern sensor system, the processing-to-flight-line-time ratio at a 1.0 MHz pulse rate (typical for 8 points/m2 acquisition) is about 76:1. This includes full processing of both image and LiDAR data, including image development, point cloud generation, line-to-line registration, image aerotriangulation, point cloud colourisation, automated data QC plots and product generation (4-band colorised point cloud and orthophotos). However, our customers’ IT infrastructures are a lot more sophisticated and consist of processing clusters. For example, running the above scenario on a 6-node cluster brings the processing-to-flight-line-time ratio down to 17:1. The processing time scales linearly with the number of processing nodes, and with high efficiency. We usually recommend 8 to 12 processing nodes for hybrid sensors.”

Edge computing is used in a couple of areas in the TerrainMapper-2. In the Hyperion2+ LiDAR unit, processing of the raw waveform data into range measurements is done in real-time using specialised FPGA software. Roth adds that this saves significant time and eliminates a ground processing step that would be required if not done in the air. On the MFC150 imaging sensors, calibration adjustments and basic image processing are also run on-the-fly. As a result, the images are already “pre-processed” upon landing. Furthermore, thumbnail images at quarter-resolution are available on landing, saving time in data review and QC checks.