Construction equipment manufacturer Komatsu has announced a partnership with Cesium, a 3D and geospatial data analysis platform, to advance smart construction.

Komatsu made the announcement at ConExpo 2020, held this week in Las Vegas. The partnership between the second largest construction manufacturer in the world and an analytics company may seem a stretch. However, in a world where construction needs desperately to digitize and take advantage of new data collection techniques, it makes perfect sense, says Rod Schrader, Chairman and CEO of Komatsu’s North American operation.

“Together, Komatsu and Cesium are bringing a new era of innovation to the construction industry. As experts in 3D data visualization, computer graphics and open source software, Cesium’s technology will help power our Smart Construction Dashboard.”

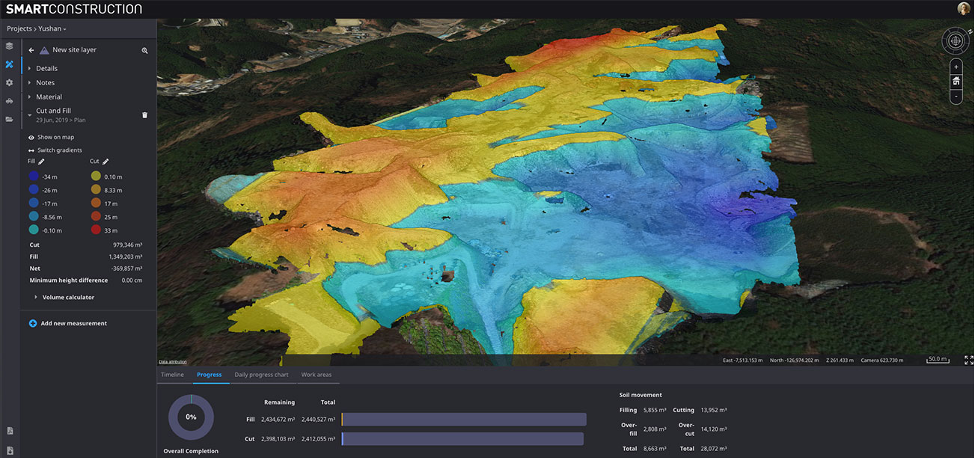

Just what is a “Smart Construction Dashboard”? The dashboard is an application used to monitor construction sites, observe progress over time, and compare the design with as-built through the construction lifecycle. Komatsu’s suite of intelligent machines, that include heavy equipment such as excavators, dump trucks and bulldozers will be able to incorporate other data to make them even more intelligent.

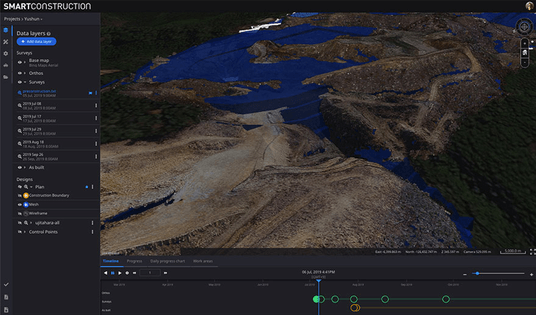

With the Cesium application, it’s easy to compare plans with reality. Here a preconstruction survey of the terrain, collected by drone, compared to a “TIN,” or triangle mesh (in blue), representing how the terrain will look when construction is completed.

Drone surveys, CAD models, GPS rover surveys and as-built data captured from other sources can contribute to the construction of a digital twin of a construction site, which has many benefits for completing projects in safe, cost-effective and less wasteful ways. On the dashboard, users can visualize projects at any stage, and analyze construction data from anywhere.

Beyond visualization, the application can then incorporate the data to provide value-added metrics, models and measurements to help inform decision making. The tools can calculate volume measurements to analyze stockpiles, examine cross sections and contours to model terrain, and look at cut and fill to determine the progress of an excavation.

This development is particularly of interest in AEC because it signals that more partnerships between data providers and equipment manufacturers might be on the way. Smart platforms and dashboards are also important so that firms are not overwhelmed by data that are being collected by disparate systems, and solutions that bring together several existing technologies.