For AEC professionals of all types and sizes, it’s a given that 3D Mapping and BIM verification are important processes in construction planning and execution. However, this isn’t always a simple task regardless of whether you’re using terrestrial or aerial mapping tools. Each of these approaches has numerous benefits associated with them, but each also has serious limitations. It’s one of the reasons Pix4D created the Crane Camera so that professionals could utilize a solution that brought together the benefits of each approach while minimizing those limitations.

The solution has been around since late 2016, but Pix4D’s Business Development Manager Julian Norton recently talked through the advantages and benefits associated with the solution during a recent webinar, where representatives from Liebherr and Losinger Marazzi joined to detail exactly how and why the Crane Camera has made such a difference on their projects.

Construction Sites, Drones, and Photogrammetry

Although the mathematics behind photogrammetry “haven’t changed in the last 3,000 years”, as Norton said, recent advances in the technique have enhanced the use of photogrammetry as a recording tool, enabling more complex representations and measurements of objects, as well as moving access to the procedure from the expert to the interested user. The most recent one is digital photogrammetry that applies analytical solutions to digital images, includes computer vision, and digital image processing techniques.

The drone and digital photogrammetry combo is quickly becoming a standard solution in many different industries, including construction, as it brings great value to all stages of a construction project. That includes the initial site survey and design, volume and elevation measurements and comparisons.

However, Norton mentioned that “flying a drone regularly on a construction site is more difficult”, since the collected data is the sort you need every day, but different factors impact planning. Equipment availability, battery, the expertise required, correct weather conditions, and legal permissions all come into play when discussing a drone flight.

“In Switzerland, flying within 50Km of an airport, a railway, busy roads or a crowd of people requires special permission. Most of the infrastructure projects that get the value from drone flying are in downtown locations, and trying to ask the local authorities to fly every morning at 9:30 next to a busy road would be almost impossible.”

The Crane Camera Solution

As a means to utilize the advantages drones provide without the logistical challenges they create, Pix4D came up with the Crane Camera solution. The theory was to attach a drone or a mobile phone to a crane and collect imagery just as a drone would. Doing so would allow users to create highly-accurate point clouds compatible with Building Information Modeling (BIM) software in the same way they would if they were using a drone.

Although many AEC professionals acknowledge the value of drone data, they also recognize the challenges of flying a drone at a construction site, which is why they were all receptive to the Crane Camera concept. After all, cranes are an inherent part of any construction project, so why not use them to gather this info?

The solution proved to be a success, and it now combines a camera with a GPS, to know where it is as the crane moves around the site, inside a waterproof box that attaches to the boom of the crane, or along the crane if using multiple Crane Camera systems for better coverage. There is also a direct connection to its power system. By using a 4G sim card, all the imagery transmits wirelessly to the Pix4D cloud platform, which uses Pix4D’s photogrammetric software to process and generate 2D orthophotos, or 3D point clouds/mesh models. These models are then ready for visualization, documentation, planning and scheduling, logistics, and maintenance. All of these results are instantly available online through a web browser, which means you can login from anywhere in the world and keep track of any project.

“We have customers who have a head office in Munich, and will look at 20 or 30 projects in South Germany remotely from their office, without the need to travel to the site”, Norton continued.

Additionally, the Crane Camera solution is completely automated, meaning it works independently of the crane operator. This automation enables project teams to get data every day at the same time without utilizing onsite resources.

“Construction projects are complex, and the schedule is always tight”, commented Pix4D’s Marketing Specialist Sabrina Cardot. “All the teams are busy, so asking a crane operator to collect images of the site every day would not work: regularity or consistency would not be guaranteed.”

Pix4D and Liebherr Collaboration

A couple of years ago, Pix4D presented its concept to Liebherr, a construction machinery manufacturer. At the time, they were focused on adopting intelligent and collaborative systems that ensure more efficient project management. This was actually the breakthrough for Pix4D and the Crane Camera Solution, as it allowed the company to have access to cranes, and get direct feedback from professionals in the AEC industry.

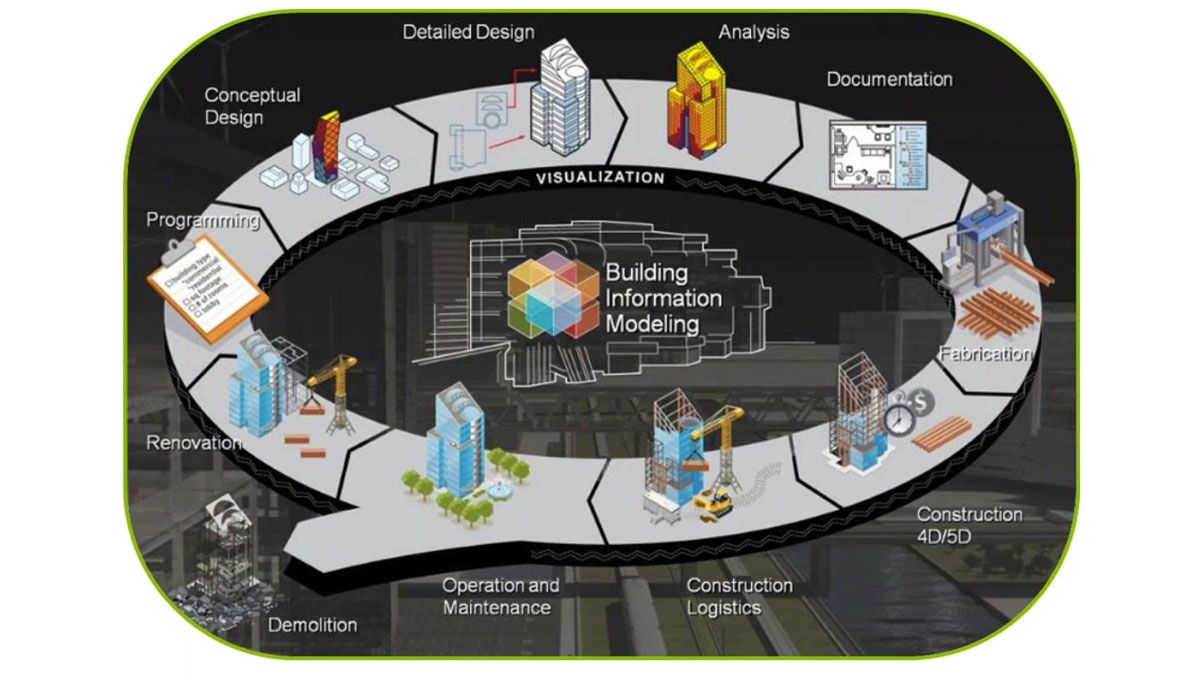

The picture above shows the building lifecycle as a puzzle, and “one puzzle is definitely the crane solution from Pix4D”, said Liebherr’s Business Development Manager Alexander Richter. “The solution of Pix4D to integrate drone technology in a Crane Camera is simple and smart at the same time. For the BIM world, the construction industry has grown and the digital lifecycle here is one big part.”

A trouble-free solution, automated documentation, target-performance comparison, and BIM integration are some of the benefits of the crane solution Richter points out.

“The digitalization on the construction site is now beginning”, added Richter. “We have started to make cranes intelligent, and we’re making equipment for the Internet of Things (IoT), and together we have the internet of cranes. We understand that cranes aren’t only for lifting, it’s also a bottleneck in the construction site, and we would like to take these benefits to improve this bottleneck with sensors.”

As Richter mentioned, the Crane Camera fully incorporates in the IoT ecosystem at the Software and Technology level. The Crane Camera solution has the power to transform a construction by providing automatic, daily measurable as-built data in 2D and 3D, on an ever-ongoing process.

Challenges and Solutions

To provide a clear idea of what the Crane Camera solution is capable of, Norton talked about some of the industry challenges, and how Pix4D’s solution solves them.

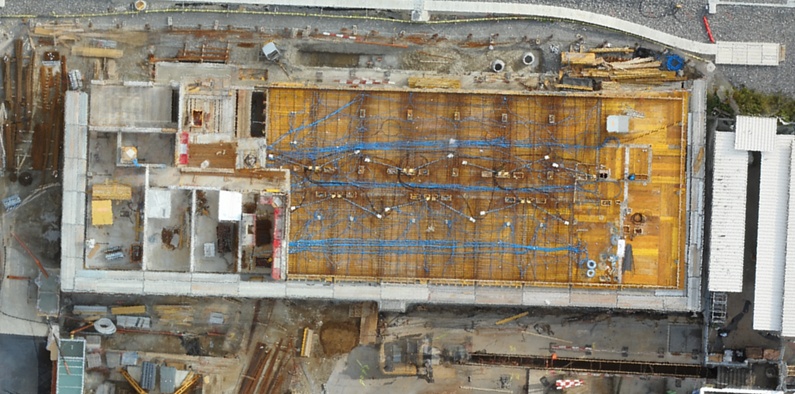

First, the lack of up-to-date information is one of the issues many AEC professionals deal with. By using the Crane Camera and Pix4D’s software, the company provides a daily site visualization tool that helps communication and operational planning. The image below shows a top-down, full-color view of a 2D orthophoto generated by the Crane Camera.

Furthermore, providing daily as-built updates in sequence with previous days is another key feature that solves any challenge related to complex schedules, which need constant monitoring to stay on time/budget.

Moreover, typical constructions projects usually have 15% rework cost. To solve this, Pix4D’s solution features an as-built vs as-design verification tool to reduce or completely remove these costs. Since the 2D generated images and the as-design plans are both orthographic, it’s possible to overlay and compare the two.

“Each morning a project manager can connect to the cloud platform to visualize the progress of the site, do measurements, upload CAD drawings to compare the as-built situation with initial plans and download all outputs to import them into other CAD/BIM software for complete BIM integration and further analysis,” Cardot explained.

In addition, the Crane Camera generates 3D point cloud data that is accurate enough to meet most construction requirements, all without the need of human resources. Also, the data is compatible with third-party software, such as Autodesk Revit, and Synchro 4D.

“With a laser scanner, you need someone to go on-site, do measurements, go back to the office to process data”, Cardot added “Additionally, the Crane Camera delivers aerial site overview which you’d otherwise need to capture with laser scanner from a helicopter. You can imagine the cost and additional time it takes with those methods, but even then, you don’t get the data you need more than once per day.”

Customer Experience from Losinger Marazzi

With a background of more than 100 years in the construction industry, Losinger Marazzi is a Switzerland-based digital construction company, which is part of the French Bouygues Group. The company has completed various projects such as the Rolex Learning Center, the Prime Tower, and the Maison de l’écriture and is now using the Crane Camera solution for its next project, the Oassis.

To talk about how the Pix4D’s solution helps during the project lifecycle, Norton invited Tom Doan, an architect at Losinger Marazzi’s and responsible for BIM design and implementation.

Doan mentioned that before they used the Crane Camera, the company was using photos from the ground team, which didn’t provide the required overview of the site. They also used drones, but the data they were getting was dependent on operators. By using the Crane Camera, the team solves both of these issues and keeps track of the progress at the construction site, “which is important, to know what we’re doing, and where the teams and materials are”, Doan mentioned. It helps them to avoid delays or mistakes that usually happen if there isn’t a constant tracking of what is happening.

Since construction projects involve many stakeholders (contractors, subcontractors, etc…) who can all be liable when mistakes or delays happen, it’s not rare to see disputes to identify who is responsible for what and when. The Crane Camera solution makes it easier to create a construction archive, and that was something Doan mentioned as being incredibly important. Having access to complete and accurate records at the end of a project is critical for the handover and for being appropriately paid for the job. Having that archive can also ensure successful long term maintenance of the building or infrastructure.

Another advantage is “to manage the team without being on-site”, Doan continued. “Sometimes the teams are disturbed by the fact that we go onto the site. So, the remote management is very important.”

In terms of how to attach the camera to the crane, Doan suggests doing it before raising the crane. If done after, the installation can take from 1 to 2 hours per crane to install the camera.

“If we have a building here which has 4 cranes, that would be 4 hours that we need to put the cranes on a break”, Doan explained.

With the Crane Camera, Doan claims quality control is easier for design teams, as they can pick up errors and measurements that the construction team wouldn’t. It is also easier to detect risky situations, such as wrongly placed materials, or missed security elements.

https://www.youtube.com/watch?v=8Z6DiXktoH4

Questions and Conclusion

At the conclusion of the webinar, Norton answered a few questions about the Crane Camera system, with one of them being how long it operates without maintenance. Since this is a completely automated solution, and it connects directly to the crane’s power source, it’s pretty much plug-and-play with no maintenance involved.

Someone else asked about how many cameras are needed per crane. “The first thing you do is contact us at Pix4D, send through site drawings and your crane deployment plan. We’ve got a software which will work out the exact location of the cameras on each crane to get the best coverage”, Norton answered. It depends on the project, but it usually means 1 up to 4 cameras per crane.

Another question was about how long it takes to generate an orthophoto of the construction site. The system takes around 15 to 20 minutes to do this, and you can do it 2 or 3 times per day if needed.

Time, cost and quality are the three subjects that matter to a construction company. Spending time learning how to use a certain technology means additional costs, which is why AEC professionals are always looking for a tool that is easy to use and reliable, and why Pix4D believes it has created just what they need.

“Coordination of construction documents is also a big challenge in the construction industry right now”, Cardot continued. “Both design and construction schedules are getting shorter and shorter, and consequently, it’s easy for important details to be overlooked. All those constraints have led AEC professionals to change the way they work and increase the need for automated solutions to gain time and subsequently money. ”

If you want to try the Crane Camera solution, Pix4D offers a pilot project program that allows you to acquire a number of cameras for your crane for 12 weeks. The company also works with you to define project milestones, and integrate the data into your BIM workflow.

Click here to watch the full webinar