The newly-announced Cobalt Design Structured Light Scanner family from FARO offers broad 3D data capture capabilities for acquiring small, complex shapes with detailed textures and color. These small, and versatile scanners are designed to be user-friendly and offered in several configurations to provide a more affordable option for many industries reaching beyond typical industrial applications.

Offered in both a single and dual series, Cobalt Design scanners are ideal for capturing small, intricately shaped objects and are offered in different mounting variations. The single series provides a defined viewing range for specific application requirements. The dual series offers scalable flexibility by providing a second measuring volume to support varying object sizes.

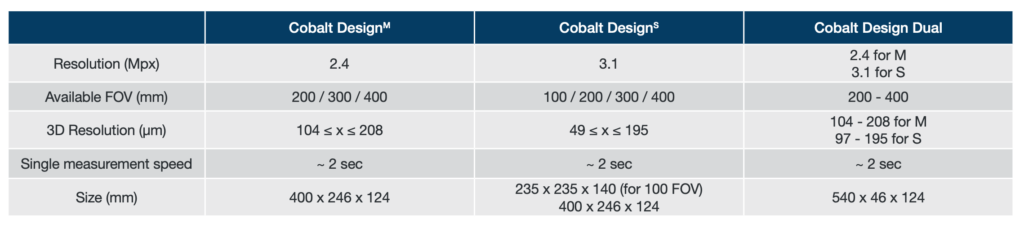

Specifications for the FARO Cobalt Design series family of scanners.

The “structured light scanning technology” uses projected patterns of lights with a camera system to capture broad areas at once – which can reduce capture time. Design scanners acquire measurement data from the full field of view simultaneously to speed up workflows in product development and visualization. The scanners capture millions of measurement points in as little as a second, with up to 3.1 Mpx accuracy for small to medium complex objects.

The new FARO Cobalt Design Structured Light Scanners capture realistic, high-quality, colored and textured scan images.

There are several features that are time and cost-saving, including the ability to set up scan parameters once, and then scan similar objects without having to redo set up steps. There are several pre-configured meshing and scanning settings that are loaded by default, so users won’t need to start their scans from scratch. Both of these features can lessen the time needed per scan, which can increase productivity and lead to faster project completion. Instead of setting up each scan individually, the carry over of these settings can reduce errors and streamline workflows, saving more costs in re-scans or correcting for inconsistencies in results.

The resulting scans are textured and can be captured in color, delivered as realistic images. These images can enable extremely detailed representations of surfaces and can capture additional detail in color.

The new scanners are designed to work with RevEng , a software package released by FARO earlier in the year that aims to be a one-stop solution for working with scans for design applications. It includes point cloud capture, mesh generation, and editing tools that allow for efficient processing of scans, and the quick production of mesh models.

RevEng and Cobalt Design scanners work in concert to reduce scanning time.

The new software and scanners are aimed at design professionals, and have applications for reverse engineering, digital cataloging, prototyping, packaging, and jewelry and fashion design. These scanners could be especially useful for historical preservation use, where there is often a need to digitize tiny physical objects while still retaining surface details like paint color on a shard of pottery.

Thorsten Brecht, Senior director of 3D Design at FARO says that the new scanners and RevEng are designed to support each other, broadening the audience of design users.

“We have elevated the 3D structured light paradigm by paralleling the development of both hardware and software, so users are able to leverage every ounce of advanced functionality of both technologies in concert.”