In 2023, a relatively young firm called Looq AI, who officially emerged from stealth earlier this year, was featured in the Intelligent Modeling category of the Edison Awards. What intrigued me was their focus on topographic surveying as a key end-use for their tightly coupled hardware and AI end-to-end, appropriately automated solution. Typically, new handheld mobile capture solutions target for asset mapping, indoor capture, architecture, space-planning, etc., not survey-grade work.

One surprising aspect was that the key capture technology is close-range photogrammetry (CRP), with a terrestrial hand-held unit. I’d tried some other CRP based solutions that weren’t quite ready for surveying, but this one looked promising. After visiting Looq AI at their HQ near San Diego, and a quick test drive, I’ve had to reevaluate my views on this type of solution. It provides an efficient and appropriately precise path to a cost-effective workflow for many types of topographic and as-built surveys.

Contrasting Sensor Approaches

Before I get to the technical details of this particular solution, I'd like to summarize and contrast other tools and techniques employed by field surveyors. Remember that surveyors (and I've been one for more decades than I'd like to admit) live and breathe precision and accuracy, typically without compromise. Such demanding professionals though, are also great at determining which specific tools and methods will yield the desired and required precisions—what tool to pick, and when.

The gold standard, for many surveying applications is shooting points with a total station (TS), which uses a laser for distance and electronically read circles for angle. TS is the electromechanical update of the centuries-old method of turning angles with a transit or theodolite and measuring distances with tapes and chains. Add robotics (where a single operator can run the rod) and the TS can bring more efficiency. However, the data is individual points chosen by the surveyor. While using codes and line-stringing can add intelligence to the capture that can help speed up drafting and modeling, the data is still a sampling of the observed features, without the spatial richness of say, a laser scanner.

GNSS rovers can be efficient for such surveying (when there is a clear enough sky view). Survey-grade precision (but not always as tight as TS surveying) is achieved through the application of real-time kinematics (RTK) corrections, network RTK (NRTK, VRS, MAC), or precise point positioning (PPP). While some newer GNSS rovers now feature limited camera and SLAM lidar augmentation, typically, individual points are captured in the same manner as with a TS.

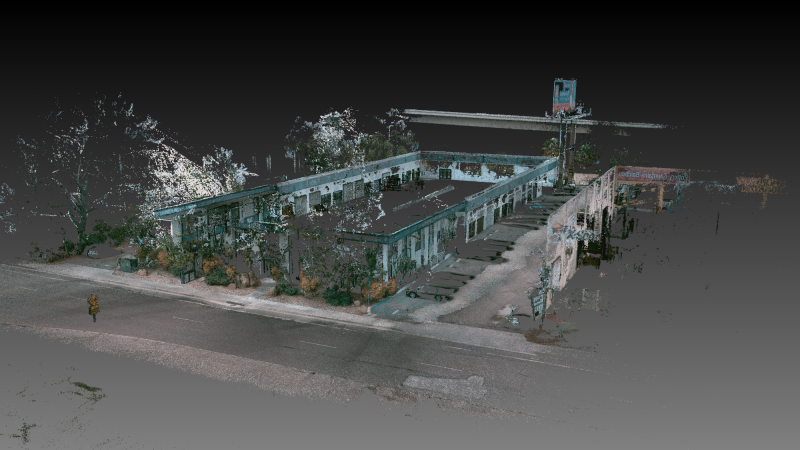

Terrestrial Laser Scanning (TLS) provides a rich 3D cloud of points, sometimes at rates of 2 million points per second. However, the individual points lack the intelligence of those shot with a TS and coded by the surveyor. This is going to sound harsh, but a common characterization of point clouds is that while they are spatially rich, they are not very smart points. There is progress; AI automation of cleaning up and classifying points in 3D clouds have greatly improved. Features can be classified as vegetation, buildings, etc. Some manufacturers have added cameras and limited scanning capabilities to TS, which can boost efficiency in certain situations.

Whether scanners are utilized through a series of static setups, mounted on mobile mapping systems, or UAS, the capture of millions of points per second, and images at highway speeds is possible. However, such a deluge of data can cause bottlenecks in the processing and drafting/modeling phases. Not to mention high costs and having to have experts on staff.

Simultaneous localization and mapping, or synchronized localization and mapping (SLAM) is a form of kinematic laser scanning that continuously references captured points to progressively register subsequently captured points—it "paints" the cloud as it goes. Even with built-in inertial sensors, there can be drift. Closing a field observation loop and post-processing can tighten things up, but there are limits to resultant precision and accuracy. Very efficient for certain applications, and can be deployed on mobile systems, backpacks, handhelds, and UAS.

CRP (and multi-sensor systems that include scanners) can be an efficient way to capture data via multiple platforms. Again, bottlenecks in the processing and drafting phases can be a drawback.

The advent of time-of-flight lidar sensors on consumer devices (smartphones and tablets) often processed together with imagery, can yield surprising results, rivalling conventional scanning—but only at short ranges. There is generally a 5m range limit for such "prosumer" devices if you are looking for anything close to survey quality. Very useful for certain applications. But, for topographic, as-built, and utility surveying, such solutions may not meet standards and may be impractical. There are prosumer lidar/image solutions that attach the phone or tablet to a handle that has GNSS+IMU. Again, very useful, but subject to range limitations.

Multi-sensor approaches, such as mobile mapping systems with scanners, cameras, and some with SLAM as well (typically for positioning stabilization) bring an even bigger deluge of data than with an individual sensor type. Each sensor type has its strengths and weaknesses, but is piling them all into a single solution for every situation wise? Are your processing and drafting/modeling phases drowning? Is there too much data to benefit from newer forms of automation?

As our surveying toolboxes grow, there is one key aspect near and dear to surveyors' hearts, that may have been under-emphasized in many of the new reality capture (mass data capture) solutions. It is spatial fidelity and registration—positioning.

With a TS, you can work from the direct observation of reference points (i.e., backsights), close traverses, localize, and calibrate. With mobile mapping systems, high-quality inertial sensors (e.g., IMU, DMI) are added, and GNSS. Data can be post-processed together (PPK+IMU) to provide the trajectory of the sensors in the travelled space. Some systems also incorporate SLAM, which helps with positioning stabilization, as well as an additional source of data points. With the addition of physical targets, such solutions can (with top components and best practices) enable centimeter precision. However, it is an extra step, albeit one of the most important steps, that you need the software and expertise to perform.

Similarly, UAS used for mapping and surveying carry GNSS+IMU. Again, adding ground control points (GCP) can bring even higher spatial fidelity for scans/images. Many, but not all SLAM -based mapping approaches rely on an IMU and progressive registration (sans GNSS), as a primary use is for indoor mapping (e.g. for architecture, asset and facility management, etc.) There are some innovative combined approaches, such as visual SLAM, where a camera helps register the point cloud. Cameras are sometimes used to help register individual terrestrial scans through progressive setups. I could go on and on about the many variations, and new approaches weekly.

Sorry for the long background, but in evaluating the Looq Platform, I needed to ruminate about the various legacy and newer approaches. For the most part, the solutions listed above can be costly: in hardware, software, labor, and processing. Many surveyors and their clients have simply become accustomed to eating those costs. What I learned from the folks at Looq was that the motivation to provide a cost-effective end-to-end surveying solution was the key driver for creating the company.

The Looq Platform

The Looq Platform is both a field capture approach and processing workflow—neither could be as effective individually as they are when combined—each had to be as highly refined as the other.

The capture component is the qCam system which creates high-resolution 3D models with automatic georeferencing from built-in GPS/IMU. Combined with the automated cloud processing solution (qAI) and immersive web application (qApp), you can analyze data and extract information for surveying, utility, infrastructure, and construction needs.

“Everything is U.S. sourced, or made by us,” said Dominique Meyer, PhD, co-founder & CEO of Looq AI. “Integration of all components, assembly, and quality control, are managed directly by us. This means we've got great customer support and ensure that all aspects of the product are reliable.”

The qCam is a handheld unit, with four cameras (one on each side, one facing forward, and one tilted upwards). It has an air travel-compatible battery (you put it on your belt), and you do data transfers via Wi-Fi. At first glance, it sounds like so many other camera-based capture systems—but then it gets interesting…

There is a survey-quality helical antenna on top and a GNSS+IMU unit inside. I was heartened to find out that they chose to go with high-quality GNSS+IMU boards from Septentrio, a GNSS product manufacturer of high repute. It wounds my surveyor's heart to see many UAS and some (low-end) mobile and backpack mapping solutions opt for low-end boards. Meyer said that the standard workflow includes a post-processing (GNSS+IMU) step, the same as with high-end mobile and aerial mapping solutions.

Looq is particularly proud of the custom cameras they specified for external manufacture. They are protected under Gorilla Glass and capture 20 MP per frame. Depending on how fast you walk during capture, the Looq Platform might be capturing half a dozen snaps per meter. One advantage lidar might have over cameras is in shadows. To deal with such situations, the Looq Platform has a ring of lights around each camera; you turn them on in strobe mode. For instance, a water valve under a car, or curbs in the shade (we ran into both during the test drive).

I was shown the calibration room in their facility; optical targets of various kinds, and a robotic arm that puts every qCam through a test and calibration phase. “What we care about is optical quality,” said Meyer. “If you look at a security camera, for example, it has some lens defects that are minor, and that visually, you don't care about. But for the engineering grade precisions we are seeking, and to enable our software to work optimally, our cameras are very sensitive to that. We control everything very carefully: optical quality, from design, to manufacturing tolerances, to production, to make sure that the whole stack is seamless.”

“We source cameras to a U.S.-based manufacturer; it is a semi-custom design to make sure that we can meet the requirements on spacing and other specifications,” said Meyer. “Then we perform advanced optical alignment, which is one of the things that often isn't done on some of the consumer level and prosumer systems.”

A question came to mind: why not put in much larger cameras? After all, my phone claims to have a 200 MP camera. “It is a balancing act,” explained Meyer. “The cameras should be as big as possible, without overloading the processing system.” It's about finding the right balance. Yes, people often boast about millions of points per second that scanners can achieve but with images (depending on range) you are looking at potentially tens or hundreds of times more potential data points.

The Looq Platform has an attachment point for your cell phone, and you control the unit from the app. You can survey offline or online. There is not much more to the operation than creating a project and task and starting the survey. The app provides a cursory preview of the images you capture as you move about the site. Apart from toggling the strobe on and off as needed, you can concentrate on your walking pattern for efficient capture (more on that later). End the survey, then find a Wi-Fi connection to log in to Looq and upload the images and GNSS+IMU data.

Regarding cost-effectiveness, the Looq Platform is priced similarly to a mid-range GNSS rover, and less expensive than many handheld mapping units (SLAM, etc.) I've tried. The standard for a Looq subscription includes both hardware and software. This has been an attractive option for many customers.

Processing

There is a lot that goes on up in the cloud once you've uploaded the data. First, it does the positioning processing: the PKK (GNSS+IMU). Then the fundamental photogrammetry; AI-based. Yes, there is a plethora of cloud services for automated photogrammetry. However, Meyer explained they have advanced the typical process further, optimizing within the image itself, not just the resultant point cloud. This is one of their "secret sauces” so I did not press for further details.

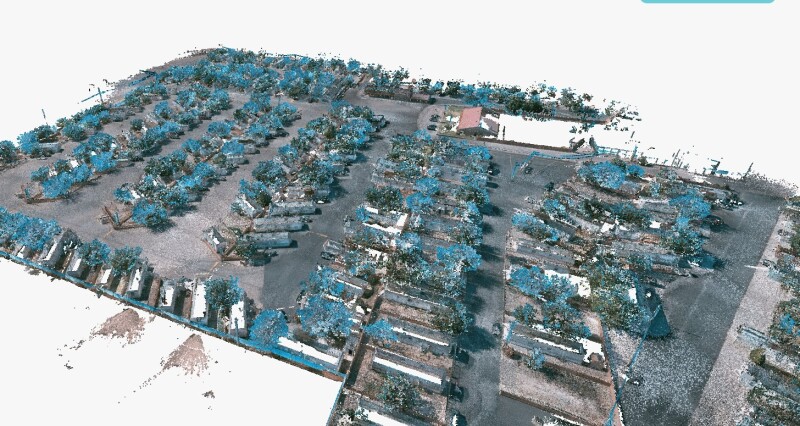

For sites that do not exceed a recommended 15-minute capture (this could be 1-2 acres), the processing, cleanup (i.e. remnants of moving people and cars) and classification will be typically complete within 24 hours. There are a dozen automated classes; power lines and infrastructure are classes they have that I do not often see with some services.

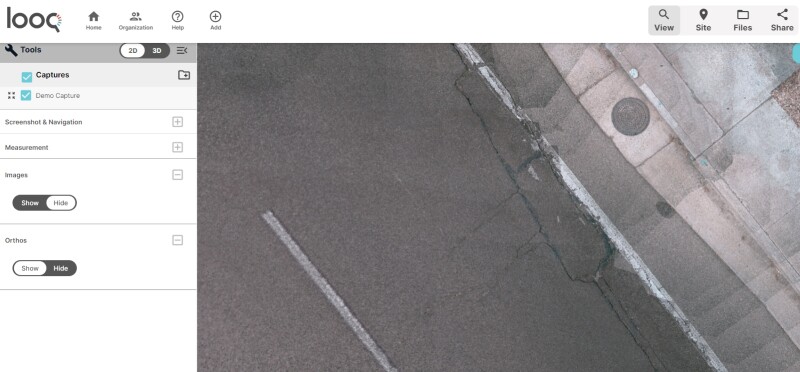

Users log into the Looq portal to manage their projects and work with/export data. You get 2D and 3D overviews. The 2D view is preferred by drafters and in the case of the very high-quality orthomosaic produced, it looks like something from a drone if it was flying at under 10 feet. In the 3D view, you can navigate the classified and unclassified data as you would in point cloud apps, but they've added quite a few features that would be expected for surveying/utility work. You can measure, cross-section, and select groups of points for export (or the whole cloud if desired) in standard formats for use in CAD or design software. There’s a tool to further register the point cloud to known points/targets, though the PPK GNSS+IMU processing would typically have registered the cloud already to RTK-grade accuracy.

You have, of course, access to all images; you can export all data—it is your data. You also have the option to have images anonymized (blurring faces and license plates); this is a requirement for some clients. This software-as-a-service (SaaS) aspect of Looq can also be bundled with the hardware, all-in-one subscription model.

A User’s Quest

Like many of us who perform as-built, topographic, and pre-design surveys, Blake Darling has been exploring various solutions to find the right fit. Darling is the director of operations at Aquawolf, a firm that manages multiple types and aspects of projects for utilities, mostly electric power, and natural gas. Services include routing, conceptual design, transmission and distribution design, and construction support.

Aquawolf is a customer of Looq AI and has three qCam units, that they deploy for projects around the Western U.S. We had a great conversation, comparing notes on our respective explorations of field capture tech and solutions; where some shine, and how others can be frustrating. I asked about their experiences with terrestrial scanning, UAS, and the “prosumer” devices like phones and tablets with ToF lidar and cameras.

"Scanners have typically been a bust for us," said Darling. "This is because of the number of setups required to get the details we need, and the time it takes the team to post-process the data. And I do not need billions of points on my surface." In the past, Aquawolf would send crews to walk entire sites and corridors, capturing everything. This would result in having substantially more data than needed. A long-range terrestrial scanner, a mobile mapper, or a UAS can bring such excess. Those can be good for certain types of projects that can benefit from the proximal context. However, the ability to focus is where significant cost-benefit can be realized.

I got the new iPhone a couple of years ago with the lidar scanner built into it," said Darling. “We immediately put that into use for large electric vaults. Those are often 25' long, 14' wide, and 10' high, but we can take the phone down there and capture the whole thing. and we need to gather a ton of data about what's going in and out of that vault as part of our job. It is great for minimal, short-range applications, but I’m not looking for absolute accuracy, I’m just looking for a scan. There are always problems with the scans, especially getting them into workflows, like with ReCap and then into Civil 3D. It just never worked out. Sort of closed the book on the phone as any kind of precision tool; it's more of a great post-fielding reference.” We agreed that for any outdoor sites of appreciable size, such tools would be impractical.

Whenever a new solution came along, Darling would consider how it might work for Aquawolf’s projects, and sometimes get demos. He heard about Looq AI by chance. One of the Aquawolf engineers was re-roofing his house, and a neighbor stopped by and mentioned the company. “We got our hands on a qCam and did a few test captures, initially without survey control. "We had a survey for an area of one of our jobs and ended up using the qCam to kind of test it—I was immediately blown away at the absolute accuracy and the internal accuracy of the point cloud that came out of it. We get a photorealistic and classified point cloud.”

Darling recounted another project, a scenario where many firms would have otherwise conventionally surveyed, or done terrestrial scans with many setups, run a mobile mapping system, or deployed a UAS with lidar and/or a camera. "We had a site that was a stretch of roadway, lined with a dense canopy of trees, about a mile and a half long, said Darling. “A drone would not have worked. I walked in a zig-zag pattern down the road. We had control pints at both ends, so I was able to confirm the absolute accuracy.”

Darling noted that they will typically place survey control at most sites, as it is a requirement for the types of projects they do. However, he said they have been very pleased with the absolute precision the Looq Platform provides by post-processing the GNSS+IMU.

“With AI processing and classification, the scan looks incredible. I can turn off the vegetation, and we have a great orthophoto, and topo survey of the site," said Darling. “Then I exported the data from the web portal and moved the data to Civil 3D with a few processing steps.” While no solution is going to be perfect for every situation, Darling says that the Looq Platform has quickly become the go-to for most of Aquawolf’s field capture needs.

Test Drive

Meyer handled the Looq Platform, made a few clicks in the app, and we stepped outside to do a circuit of their building. It only took about 10 minutes to walk around the building, making (recommended) gentle “snake” patterns through the wider areas of the parking lots, reaching down to capture curbs under trees, some survey marks they have set, going around some poles and structural columns, and turning on the strobe in shadows

Looq has a surveyor on the team: Lucas Fraser, VP of Product, who explained the recommended capture methods, though it is quite intuitive to use. From a cold start, or if it has been in the box or indoors, you will want to let the GNSS acquire sats, and let it warm up for about 15 minutes. After that, you can start capturing and move on to subsequent captures.

“No special handling,” said Fraser. “Though you might want to avoid sudden changes in trajectory, you can walk at a normal pace and aim it towards the features you want to capture. What you see, it sees.”

This includes power lines. One of the bugbears for surveyors is shooting the sags of power lines. They can be tough to shoot with a TS, and you can set up a high-end scanner, but you may still have difficulty. The nice thing about images is that if you can see it in multiple images, it will show up in the data.

I do intend though, to do a head-to-head test at some point. Fraser said that this is what many of their customers, especially surveyors, do. “We show up for a demo, and they take us to a test site or wall that they’ve scanned, or shot with a [total station], or other methods.” They usually find it meets their needs, and indeed, most of their customers so far have been surveyors.

The Genesis

“We always believed that bridging the gap between the physical world and digital assets requires a key interface between how to capture the data and process it efficiently,” said Meyer. “And that is why today we have hardware technology in addition to our software AI. Clients care about extracting direct and immediate critical value features. We care about saving time in the field—safely—and savings in the post-processing, making it easy to go from data capture to deliverables. This is crucial for different types of infrastructure, such as power utilities which are poised for significant growth as updating the electrical grid is of national importance."

Looq emerged from the minds of some very bright people who recognized a problem and then realized that their areas of expertise could help solve it. This wasn’t a solution looking for a problem, which is all too common.

Meyer earned his undergraduate degree in physics at UC Sand Diego, followed by a PhD in computer science and engineering. During his PhD, he was building camera systems for autonomous vehicles. Such systems have safety-of-life requirements, and there is little room for compromise. He met at UC San Diego, Shreyas Niradi, co-founder and Chief Science Officer of Looq that they would soon launch. The two discussed industry sectors where 3D capture, and modeling were costly and inefficient. Infrastructure stood out: civil, transportation, vertical construction and more, but especially for utilities. The story goes that one night, in Meyer's garage at 2:00 a.m., they decided to create Looq. Several approaches were considered before settling on the current solution.

In the lobby of their offices, I had noticed a small track robot with cameras attached to a central pillar. "One idea we had was to try autonomous mapping," said Meyer. "But we realized that the robot could not make the same judgments in the field as a surveyor. It does not know that you have to open the gate at the end of the field or step over a ditch. The human is essential. What we have done is to make their field work as simple, safe, and efficient as possible. We optimize what they capture up front to ensure the best results from the AI processing.” As we often hear: AI might not take your job, but someone that is good at using it could. I have always thought that surveyors will make great coaches for geo-robots.

Leveraging AI, especially if fed the tightly controlled and refined input data from their hardware, was fundamental to Looq’s vision. And working with images provided more opportunities to improve on the norm than if they had chosen to work with lidar. “Look at lidar classification; we're seeing limits on how good that can become,” said Meyer. “You're fundamentally limited by the signal-to-noise ratio of your datasets. In our case, we've got two orders of magnitude more and better data to work with. And that is where Looq is able to leverage operating capabilities to enable a fundamental AI shift in our recognition algorithms.”

There are always going to be differing views on what sensor types or combinations will work best for field data capture and processing automation. However, CRP has always stood for its cost-effectiveness, though underutilized. The Looq solution may not be completely unique, but I believe it overcomes many shortcomings of handheld CRP solutions from the past, and many present-day offerings. It is not that the old ones and new ones are “bad” per se (though I’m sure I’m not alone in having been burned by a few), it is just that this solution is optimized for and appears to work very well for small-site surveying and infrastructure capture. While this is not a direct endorsement, I would encourage folks to give it a serious look (or Looq).