A number of industries are practically bursting with people who could benefit from the power of 3D measurement tools, but don’t know it yet. If they do know it, they just haven’t found a tool they can afford or use properly.

DotProduct is among a group of companies aiming to bring 3D-imaging tech to that group. To test how easy their product is to use, I performed some scans myself using the DPI-8 kit.

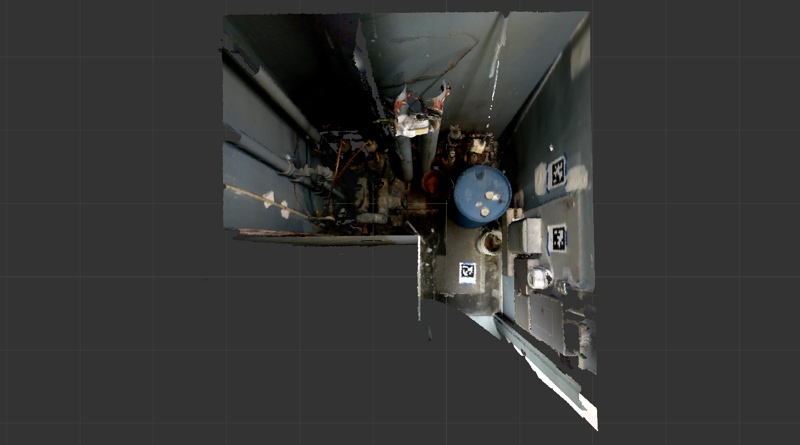

For this test, DotProduct’s marketing manager Chris Ahern visited me at the SPAR 3D headquarters in Portland, Maine. We powered up the DPI-8, found the gnarliest looking room in the whole building (a utility room hidden deep in the building) and got to work.

A utility room at SPAR 3D Headquarters

My impressions? I found it just as intuitive to use as DotProduct said. The hardware itself is simple—a tablet and some sensors mounted on a handle, pre-calibrated and ready to go after a quick warmup period.

I simply pointed the tablet at the parts of the room I wanted to scan, and followed the on-screen feedback. It changed colors when I had done my job correctly. When I got over-excited and moved too quickly, the Phi.3D software couldn’t keep up. But that was simple enough to correct, as DotProduct designed their rig so it instructs me to return to a part of the room I had already scanned, at which point the software re-oriented itself.

Processing the data was just as user-friendly—I just clicked on another tab within the software, set a few parameters, and waited for the job to complete. All said and done, it only took me one short tutorial before I felt comfortable with the idea of scanning a room and processing the data by myself.

Part of the reason the Phi.3D software is so easy to use is because it piggybacks on a user interface that most of us are already familiar with (Android’s mobile OS). This means that you already know how to use it before you get your hands on one. Opening the software on the DPI-8, you’d be forgiven for thinking you had opened any other app by accident.

Another view of the utility room

I should mention that, though I didn’t get to test them personally, Ahern showed me a number of tools DotProduct has developed for scanning in slightly more difficult situations. This includes printed targets for improved alignment and a light for for scanning dark places (both of which Ahern put to liberal use in the scans you’ll see above). He also showed off DotProduct’s new integration with Brunson reference bar kits, which offer a known length that helps to calibrate scans–making the scanning process both faster and more accurate.

Possible Uses

If you need quick but reliable 3D data, the DPI-8 could be what you’re looking for.

For instance, if you’re an asset owner, you could use the DotProduct to capture an existing facility for a retrofit, and all without having to bring in outside help. If this is the kind of thing that you do often, it could make a big difference to your bottom line.

On a construction site, the DotProduct scanner is ideal for capturing progress. Scan any new additions, and tie them back into the file. As Trimble’s Brian Williams, segment manager for field solutions once told me, “as you’re going through your daily build, you can quickly capture the data, see the progress of where things are at, and then you can start looking at things like–What has been built? What hasn’t been built? You can compare that to the design, the construction model, and use that to figure out where you’re up to, and who needs to be scheduled to come in next.”

As I experienced for myself during the test run, the DPI-8 and Phi.3D combo is easy enough to use that asset owners and construction workers will find it a cinch to gather 3D information on the fly. As such, it stands a real chance of bringing 3D technology to the masses, and all of the benefits of precision measurement with it